Our services

Product Development

We translate ideas into practical and functional products or solutions. Development is a crucial process where we work to refine and optimize according to your requirements and/or production. This is essential to ensure that the final product operates as intended and meets the desired specifications. It's an approach aimed at delivering validated and optimized solutions.

In essence, If you know what you want, we can make it a reality. We optimize and ensure that the solution works in production and in reality to your requirements.

We don't have production for one simple reason: no one can master all technologies in one company. We want to deliver the best solution for each specific product, rather than trying to fit a product into an production process.

With this philosophy, we create happy customers and satisfied manufacturers by facilitating the best solutions.

Are you searching for the perfect solution? We offer the right one for you! Book a free online meeting right here or call +4522398040

We use:

Mouldflow analysis

Mouldflow analysis acts as a virtual guide to the plastic product moulding process. We utilize computer modeling to simulate how plastic melts and flows inside a mould under various conditions such as pressure, temperature, and velocity.

The benefit? It aids in optimizing the molding process and prevents issues like air bubbles, shrinkage, or deformations in the final product. This way, we can digitally fine-tune the parameters and predict how different changes will affect the quality and performance of the molded product. It saves both time and money by avoiding costly mistakes and the need for numerous physical prototypes and expensive tooling alterations.

Depending on your requirement specification, Mouldflow analysis is a process that can involve up to three steps:

1. A fast and rough analysis to pinpoint potential problems. Also inexpensive.

2. If we find issues that need clarification, we proceed with optimization.

3. If the optimized result is still unclear, we run a Design of Experiments (DOE).

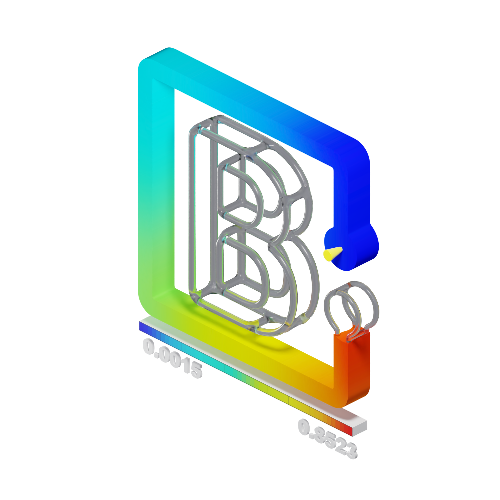

A DOE is a systematic approach used to explore and understand the effects of multiple variables on the injection molding process. It involves running a series of simulations where key factors—such as temperature, pressure, part geometry —are varied systematically. This identify the optimal settings and understand how these variables interact to affect the quality and tolerances of the molded part.

Often, the reason to use it can be quality assurance, process, or cycle time optimization. Below, you’ll find a simple slider showing the gains from cycle time optimization. In reality, it is complex but can save a lot of time and resources. Talk to our engineers to find out if your product can benefit from a mouldflow analysis.

Production Time and Extra Parts Calculator

Adjust the sliders to see how much time you will save per year and how many extra parts you can produce by modifying the cycle time and the number of cavities.